The maintenance of large diameter threads can be quite

complicated and rather costly. Due to their larger size

and weight, it is often difficult to work on the damaged

threads at a workbench or on a table. The repairs have

to be conducted on the spot. Furthermore, the larger

diameters require larger tools which require larger

clearance to complete the repair. Traditionally, one would

dismantle the entire part, bring it to the workshop and

rethread it there. Oftentimes this may not be feasible to

do by hand, subsequently requiring expensive power tools.

Alternatively, one could use a thread file and quite a bit

of elbow grease. Both of these methods are aggravatingly

arduous and time consuming.

Luckily, Nes has an easy and cost effective solution to the

problem of repairing large diameter threads. Our internal

and external thread repair tools slide into the thread and

adjust to its diameter and pitch automatically. A couple

rotations and boom, fixed with barely any effort! Nes

thread repair tools don’t only reduces the time and effort

put into the job, they also save you some serious money.

You no longer need to spend large quantities on taps, dies

or power tools as the Nes internal and external thread

repair tools can do it all with perfect results every time!

•

Automatically adjust to the thread diameter and

pitch- no prior measurement of the thread

needed

•

Canbeusedonleft-handorright-handthreads

•

Both inch and metric, coarse and fine

•

Able to dowhat taps and dies cannot, such as

repairing a component that is damaged at the

end of the thread

•

InternalandExternalthreadrestorershavethe

capability to enter BELOW the damaged area

and work outwards to complete the repair

•

High quality cutting tool steel Blades (internal

Nes blades – HSS, external Nes blades - O1)

guided by the undamaged section of thread in

order to re-groove the damaged section

Nes - Thread Repair Tools for Large Diameter Threads

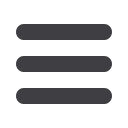

Nes Internal Instructions

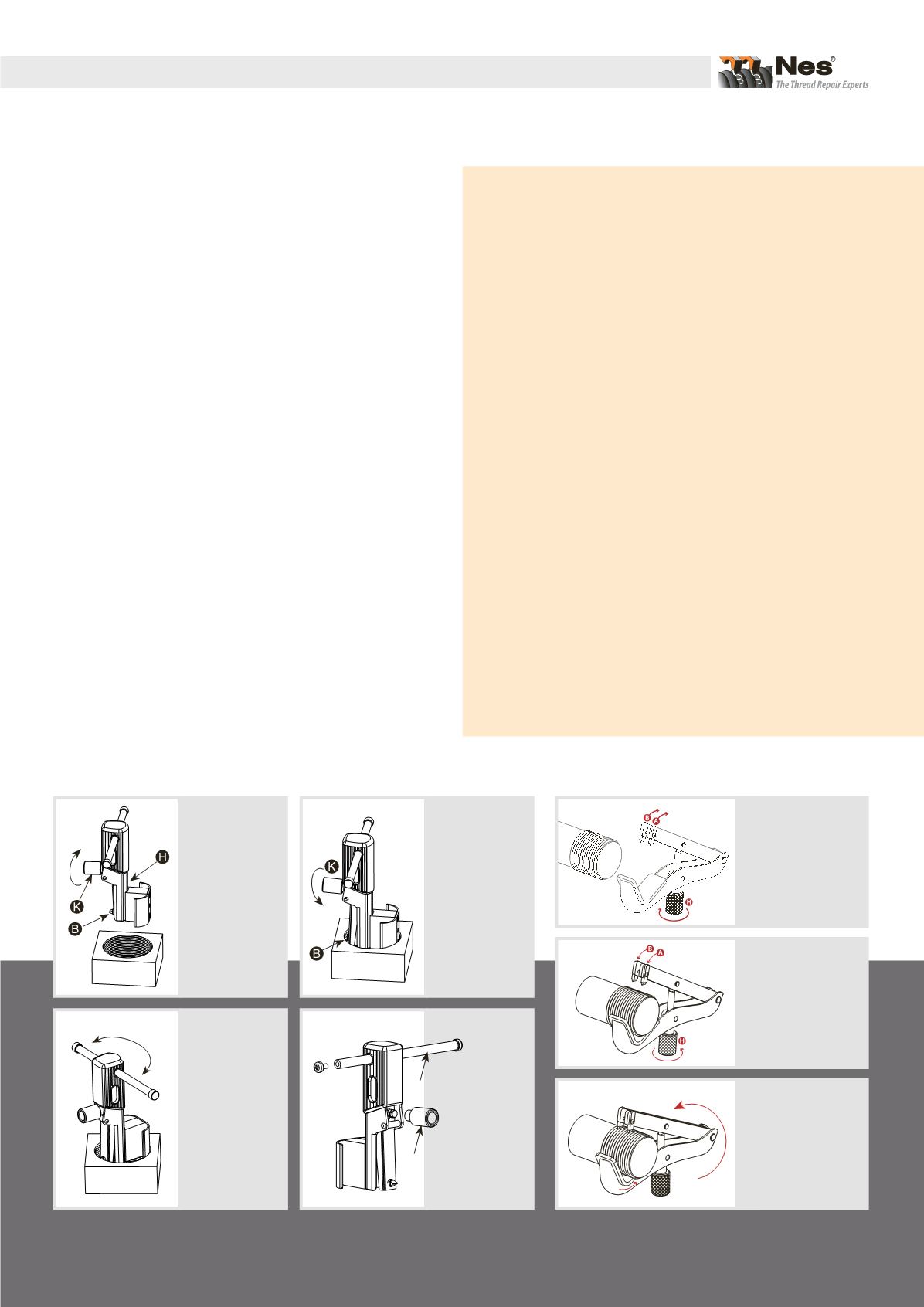

Nes Enternal Instructions

2

1

1

2

3

3

Turn knurled

knob (K) to

fully retract the

blade (B) into

the housing (H).

Insert Nes tool

intothethreaded

hole or bore to

the repaired.

Rotate Nes by

the cross-rod,

as shown, in the

desireddirection.

Turnknurledknob

(K)toextendblade

(B) into a thread

groove on an un-

damagedsection

and tighten – by

hand only.

Open

Turn handle (H) to

raise blades (A+B).

PlaceNes3overbolt

to be repaired.

Close

Turn handle (H) to

lower blades (A+B)

into grooves of

thread and tighten.

Rotate

Rotate Nes3 in

direction of the

arrow only.

Removable Parts